Area Manager Shane Maron discusses P041 with the Lean Manufacturing class instructor Friday.

North Plant 2 hosted a group of visitors Friday, diving deep into 5S and Safety training while working with Lozier equipment. North Plant Area Manager Shane Maron called the coursework a fantastic opportunity for advancing knowledge.

“It’s fantastic that Lozier made this class possible for us,” Maron said. “Learning new ways of doing things is helpful for continually improving our culture.” Initially, Maron and fellow Area Manager Matt Banker enrolled in the class, but upon Lozier accepting the opportunity to host coursework on site, the school offered several free seats to the classes, which allowed Roy Tyson and Andrew Dragon to attend.

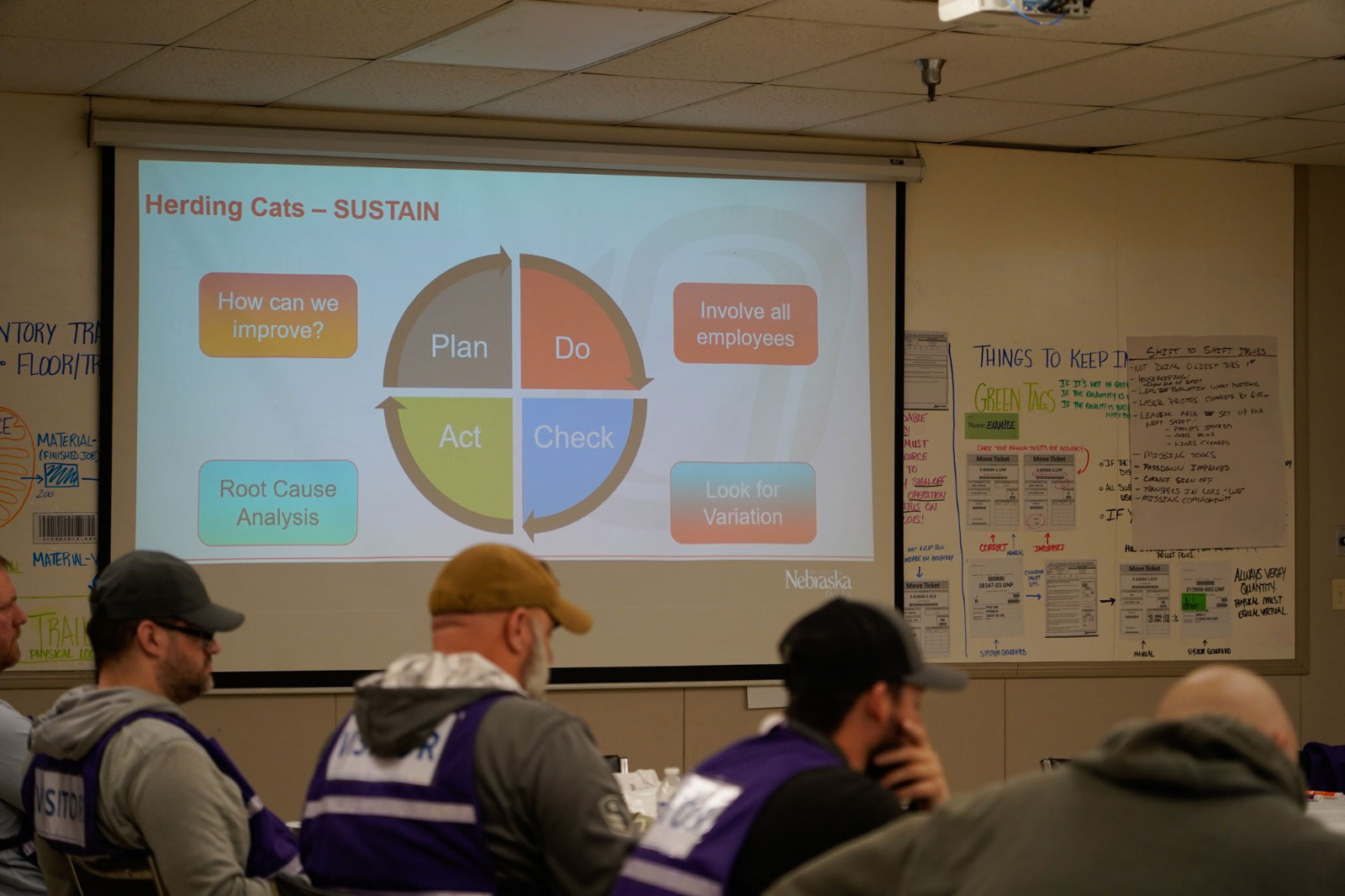

Classroom discussion included an exercise of the value of the 5S approach to manufacturing, entitled “Herding Cats.”

The education, offered by the Nebraska Business Development Center and University of Nebraska-Omaha’s College of Business Administration, is a Certificate program covering 56 hours of education within an 18-month window. Friday’s class covered the 5S pillars and safety in the workplace, using some classroom work in combination with hands-on learning with P041, the press that recently arrived as part of the OneOmaha evolution.

Shane Maron (third from right, facing away from camera) discusses P041 while classmates look on, including Matt Banker (right) and Andrew Dragon (second from right)

Students from a number of employers were on site, lending their insight and professional experience to the class, which Maron said was an added benefit from hosting the coursework.

“Lozier is committed to improvement, and classes like this are a great opportunity to get that improvement,” Maron said. “We’ve learned a lot already and we’re excited to share that knowledge with everyone here.”

The class will return to the North Plant April 11 and 12 to cover the Concept of Value Stream Mapping. Other lessons include Principals of Lean, Leadership, Cellular Flow and Change Management.